- Home

- About Weber

- Business Layout

Overseas Business

Overseas Business Affiliated Brands

Affiliated Brands Production base

Production base - Products

- News and Information

- Join Weber

Global ODM Electric Water Heater Expert

Anhui Weber New Energy Heating and Water Supply Equipment Co., Ltd. is an outstanding ODM+ company in the electric water heater industry, ranking third in domestic production and sales volume, following Midea and Haier. The company is committed to providing well-known customers with high-quality products and services. Since its establishment in 2014, it has more than 500 employees.

The company has passed the three major management system certifications of quality, environment, and safety. After years of technological transformation, it has continuously improved its R&D and manufacturing levels, and has independent scientific and technological achievements and high-tech products, including multiple inventions. The F30X series of products is rated as a national-level green design product. The company has been successively rated as a high-tech enterprise in Anhui Province, a provincial specialized and sophisticated small and medium-sized enterprise, a provincial industrial design center, a provincial digital workshop, a provincial enterprise technology center, a provincial 3A credit enterprise, a private science and technology enterprise, Ma'anshan City Engineering Technology Center, and a municipal smart factory, etc.

Base covers an area

Outstanding employees

Annual production capacity

Products exported worldwide

Possessing global leading equipment and processes, with 2 inner tank production lines and 5 assembly lines.

Kawasaki robotic end cap line

WAGNER spraying line

APES inner tank welding line

Double-head edging machine

EISENMANN-electrostatic dry powder enameling line

Dual-tank welding robot

The enamel sintering process is relatively complex, generally divided into 6 processes, and excellent products require precise temperature control in these 6 processes, that is, the temperature-time curve must match the characteristics of the enamel powder.

High-temperature sintering precise temperature control at 850 degrees.

The dry powder enamel coating on the inner tank is more evenly distributed

The adhesion level can reach grade 1-2, far exceeding other process technologies and industry standards of not less than grade 3.

• Solves the problem of gaps in the circumferential seam of plug welding;

• The circumferential seam can achieve full enamel coverage;

• Has better pressure resistance and pulsation performance;

• Can greatly increase the service life of the inner tank;

• Reduces the market leakage rate of the inner tank circumferential seam by 50%;

The quality and performance of the entire machine's inner tank are significantly ahead of industry standards

• DFMEA

• Safety failure analysis

• Reliability testing

• Butt welding/TIG welding

• Robotic end cap stamping line

• Material turnover protection

• IT anti-error/key component binding management

The first in the industry to have a national CNAS certified laboratory

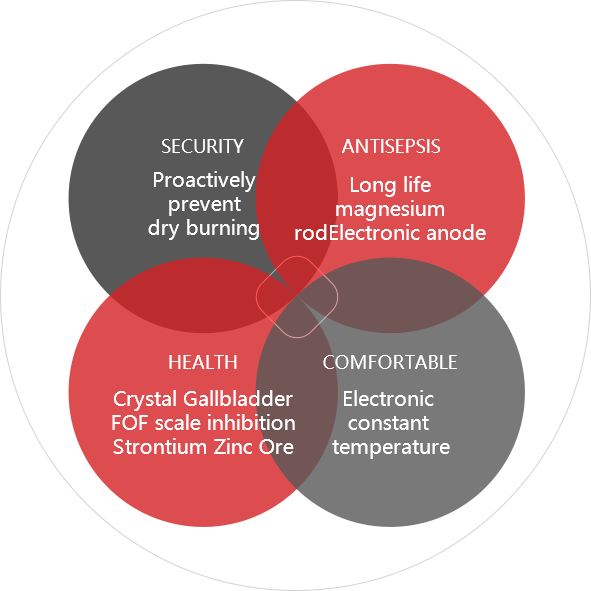

• Unique industry technology, detects water level, actively prevents dry burning

• Long-life resistive magnesium rod, can extend life to 8 years, no need for frequent replacement

• Zero-additive beauty wash, zero metal, zero rust, zero magnesium scale

• Innovative built-in scale prevention, modular structure, easy to disassemble and assemble

• Electronic constant temperature technology, dual-adjust cold and hot technology, better constant temperature performance

No. 500 Yinhuang West Road, Economic and Technological Development Zone, Ma'anshan City, Anhui Province

Ms. Li, Ms. Rui

Phone: 0555-2230282

Address:

Foshan Shunde District Ronggui High-tech Industrial Development Zone Technology Industrial Park Jianye Road D01Service Hotline:

+86-757-28988630Copyright © 2024 Guangdong Weber Electrical Appliances Co., Ltd. All rights reserved 粤ICP备14087702号 Yue ICP Prepared 14087702 Number

Technical Support:Foshan Website Construction